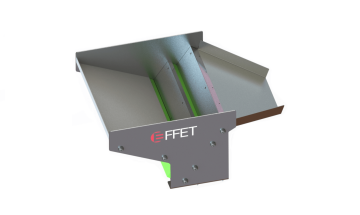

PROFESSIONAL FEEDING TECHNOLOGY

We design and manufacture purely Czech professional feeding technology for your production. Our products are the result of more than 30 years of tradition in the field of automation and development of single-purpose machines under the Trystom brand. Our technology will improve and streamline your manufacturing proces. We not only manufacture the feeders and their other accessories, but also tune and install them directly at your site. We will train your operators and fully service them. Save time and money with fast delivery and free design of the ideal solution.

We create precise and technically sound solutions and are not afraid of non-standard challenges.

Watch how EFFET feeders work

For more information, please contact us.

Do you want to know more about feeding technology? Do you want to assess the feasibility of your project for free? Contact us at +420 581 113 000.