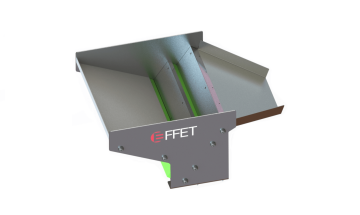

Bowls vibratory feeders: Conical hopper

Feeding of small material

The function of the circular vibratory feeder is to feed and orient the loaded parts into the hopper. Do you need to feed large quantities of small parts to streamline production? Then the EFFET cone hopper is the right choice for you.

Use: Feeding of small material

Circular vibratory feeders are designed for feeding and orientation of poured parts into the hopper. They are an ideal choice for feeding small quantities in large quantities. They also save you time.

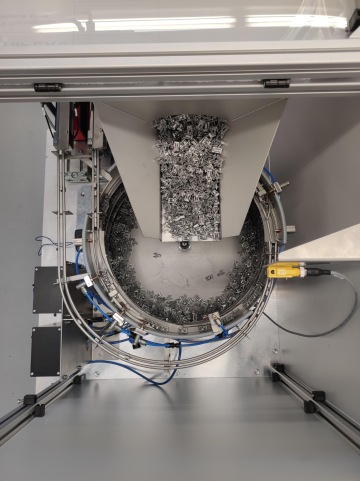

How does the Vibration Feeder work?

The circular vibration feeder is composed of a vibration source and a hopper. The source of vibration causes the material in the hopper to vibrate, causing the parts to move up the track.

Conical hopper variants:

- BVF 180

- BVF 280

- BVF 380

- BVF 480

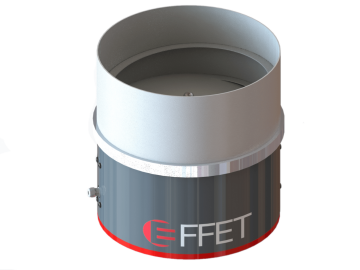

Bowls vibratory feeders: Cylindrical hopper

Feeding of small material

The function of the circular vibrating feeder is to feed and orient the poured parts into the hopper. Do you need to feed large quantities of small parts and make production more efficient? Then the EFFET roller hopper is the right choice for you.

How does the Vibration Feeder work?

The round bar feeder consists of a hopper and a source of vibration. Due to the vibration source in the hopper, the material vibrates and the workpieces move up the track.

Variants of cylindrical hoppers:

- BVF 180-C

- BVF 280-C

- BVF 380-C

Reviews of the vibratory feeder by ROBERTSHAW

We have already produced more than one million pieces on the production line from Trystom with EFFET feeder and it runs perfectly. We were satisfied with the implementation process and the deadline was quick beyond our expectations.